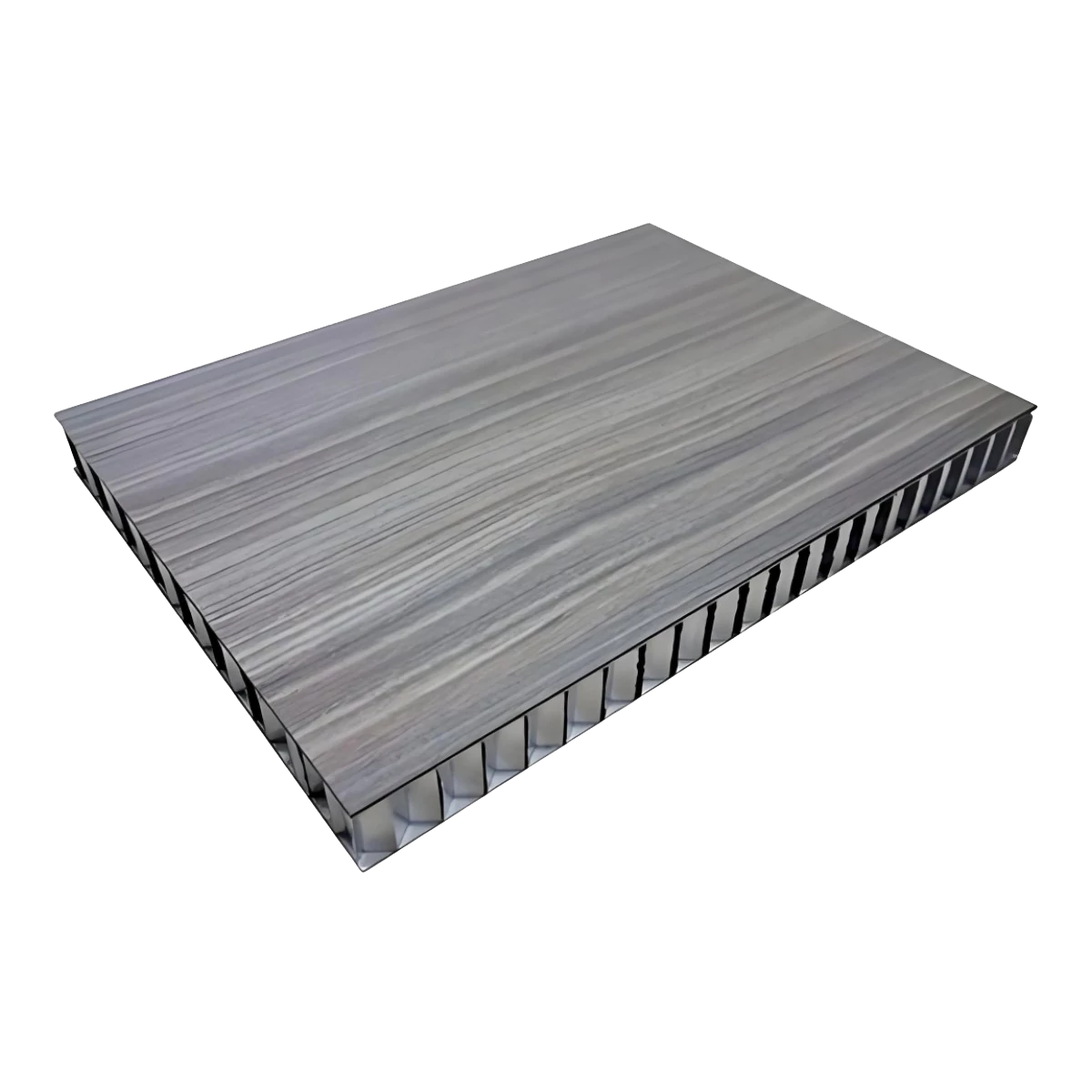

Sandwich aluminum honeycomb panel

Material composition

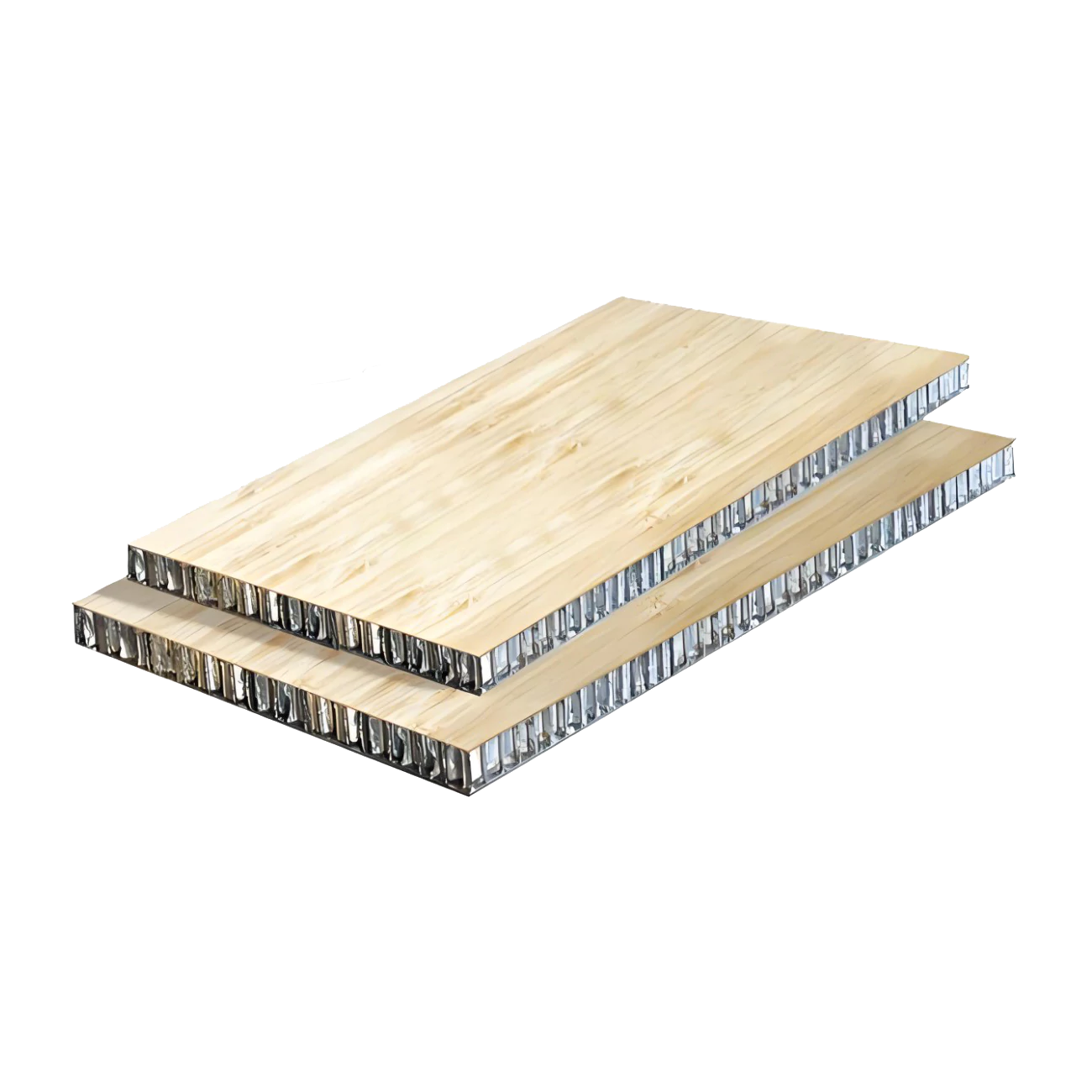

Outer layer aluminum plate: commonly used alloy 6061 or 5052, which has good corrosion resistance and welding performance.

Honeycomb core: usually made of aluminum alloy or plastic material, hexagonal in shape, providing excellent mechanical properties.

thickness

Aluminum plate thickness: usually 0.5mm to 3mm.

Honeycomb layer thickness: usually 10mm to 50mm, customized according to needs.

density

The density of aluminum honeycomb panels is generally between 0.3 and 0.8 g/cm³, depending on material selection and structural design.

Products Description

Aluminum honeycomb panel is a lightweight, high-strength composite material widely used in aerospace, automobiles, construction and shipbuilding. It consists of two layers of aluminum plates and a honeycomb structure in the middle, which has excellent compression resistance, bending resistance and sound insulation properties.

Main parameters

Material composition

Outer layer aluminum plate: commonly used alloy 6061 or 5052, which has good corrosion resistance and welding performance.

Honeycomb core: usually made of aluminum alloy or plastic material, hexagonal in shape, providing excellent mechanical properties.

thickness

Aluminum plate thickness: usually 0.5mm to 3mm.

Honeycomb layer thickness: usually 10mm to 50mm, customized according to needs.

density

The density of aluminum honeycomb panels is generally between 0.3 and 0.8 g/cm³, depending on material selection and structural design.

Compressive strength

Depending on different materials and structural designs, the compressive strength of aluminum honeycomb panels can reach hundreds of megapascals (MPa).

thermal conductivity

The thermal conductivity of aluminum honeycomb veneer is about 150 W/(m·K), which has good performance in thermal insulation applications.

acoustic performance

Aluminum honeycomb panels can effectively reduce noise. The acoustic performance depends on the structure and material of the honeycomb, and usually has good sound insulation effect.

advantage

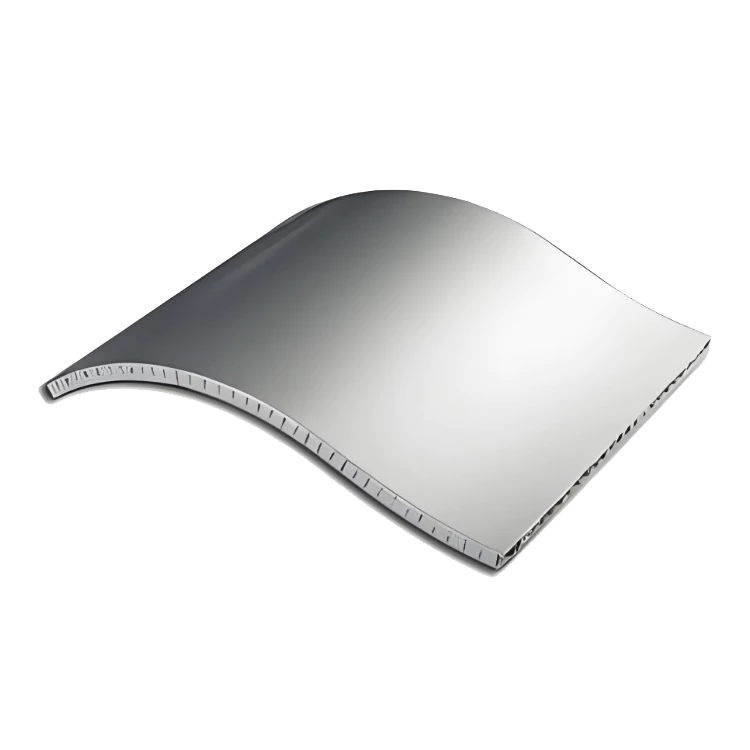

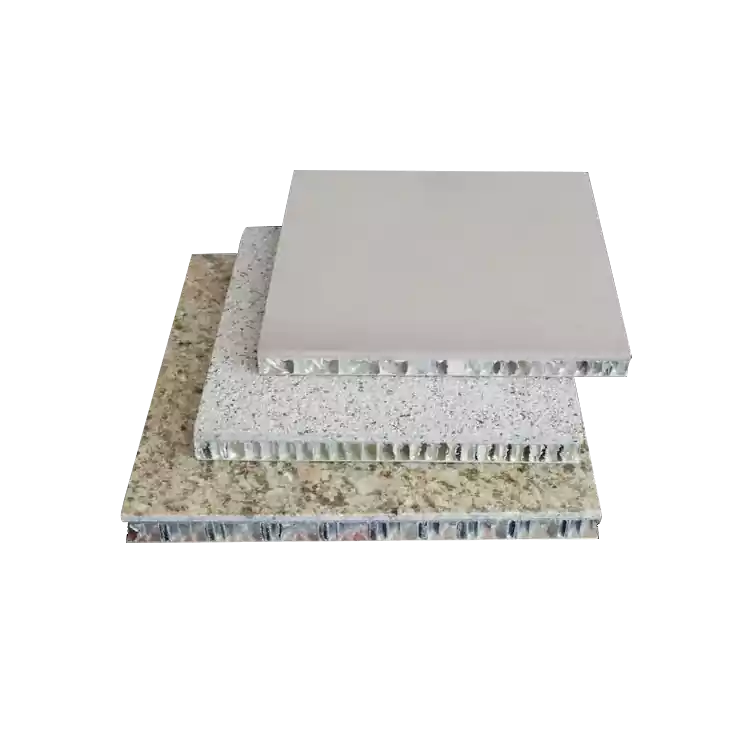

Lightweight and high strength: Aluminum honeycomb panels are lightweight while maintaining high strength, making them suitable for weight-sensitive applications.

Excellent corrosion resistance: Aluminum material has excellent corrosion resistance and is suitable for various environmental conditions.

Good processing performance: Aluminum honeycomb panels are easy to cut, weld and form, and are suitable for a variety of processing methods.

Environmental protection: Aluminum is recyclable and meets the requirements of sustainable development.

Application areas

Aerospace: Used in the interior and exterior structures of aircraft to reduce weight and improve fuel efficiency.

Architecture: As curtain walls and interior partitions, providing aesthetically pleasing and lightweight solutions.

Automobile: Used in body structure and interior to improve safety and comfort.

Ships: Applied to hull structures to increase strength and reduce weight.

in conclusion

With its light weight, high strength and excellent corrosion resistance, it has become an ideal choice for many industries. With the continuous development of technology, the application fields and market demand of aluminum honeycomb panels will continue to grow.

FAQ

Does the product support customization?

Yes, our products are all factory direct sales and can be customized according to customer needs.

What are the color options for Slatted Acoustic Panel surface?

Melamine Surface、Engineered Wood Surface、Natural Wood Surface、Baseboard Color

What is the thickness of the wood veneer of the Slatted Acoustic Panel?

Our product’s standard wood veneer thickness is 0.45mm and 0.25mm.

How many facets can a Slatted Acoustic Panel have?

Slatted Acoustic Panel has three covers and one cover.