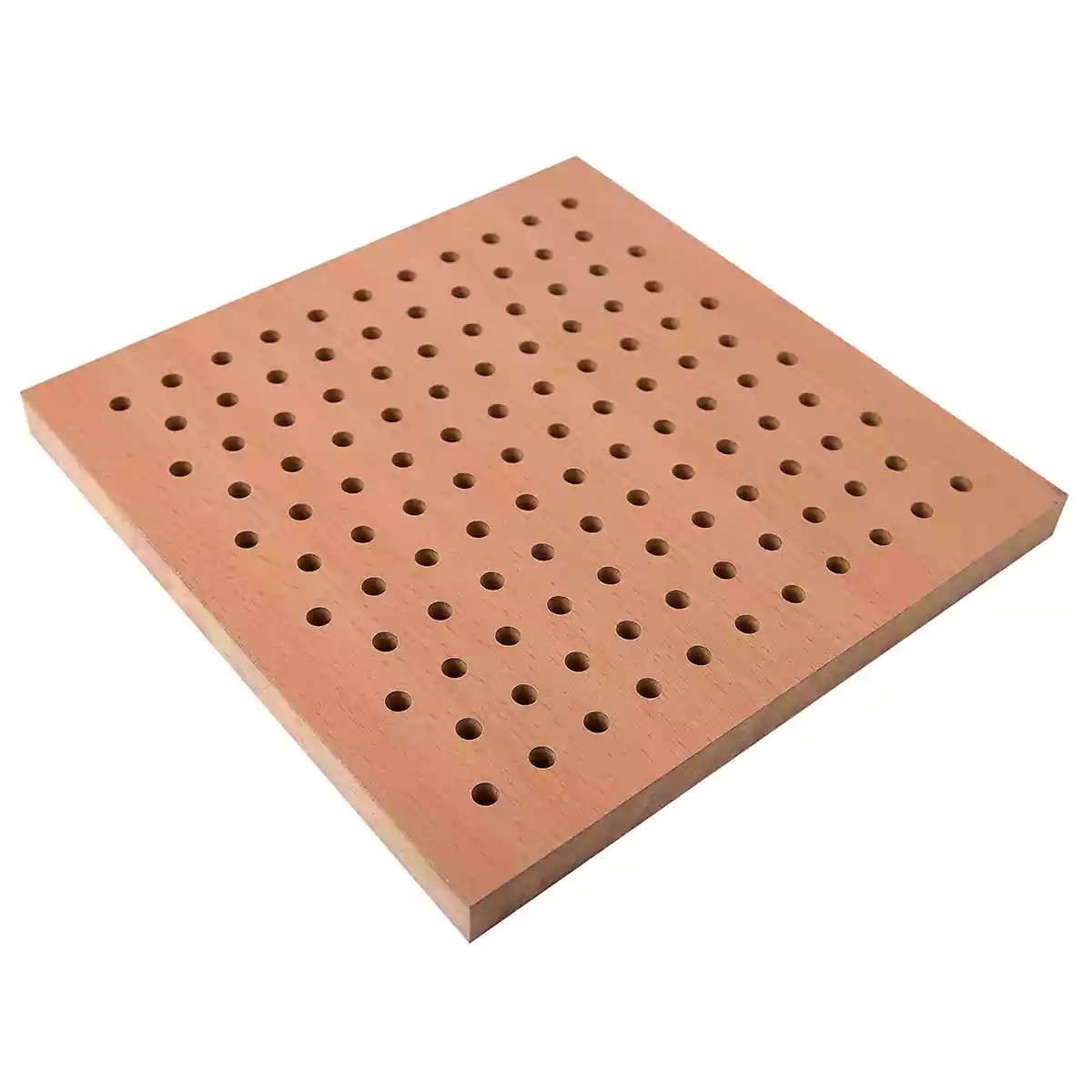

perforated wood sound absorbing board

1. Base material: medium density fiberboard (MDF) or perforated gypsum board

2. Surface treatment: melamine veneer, veneer, spray paint, etc.

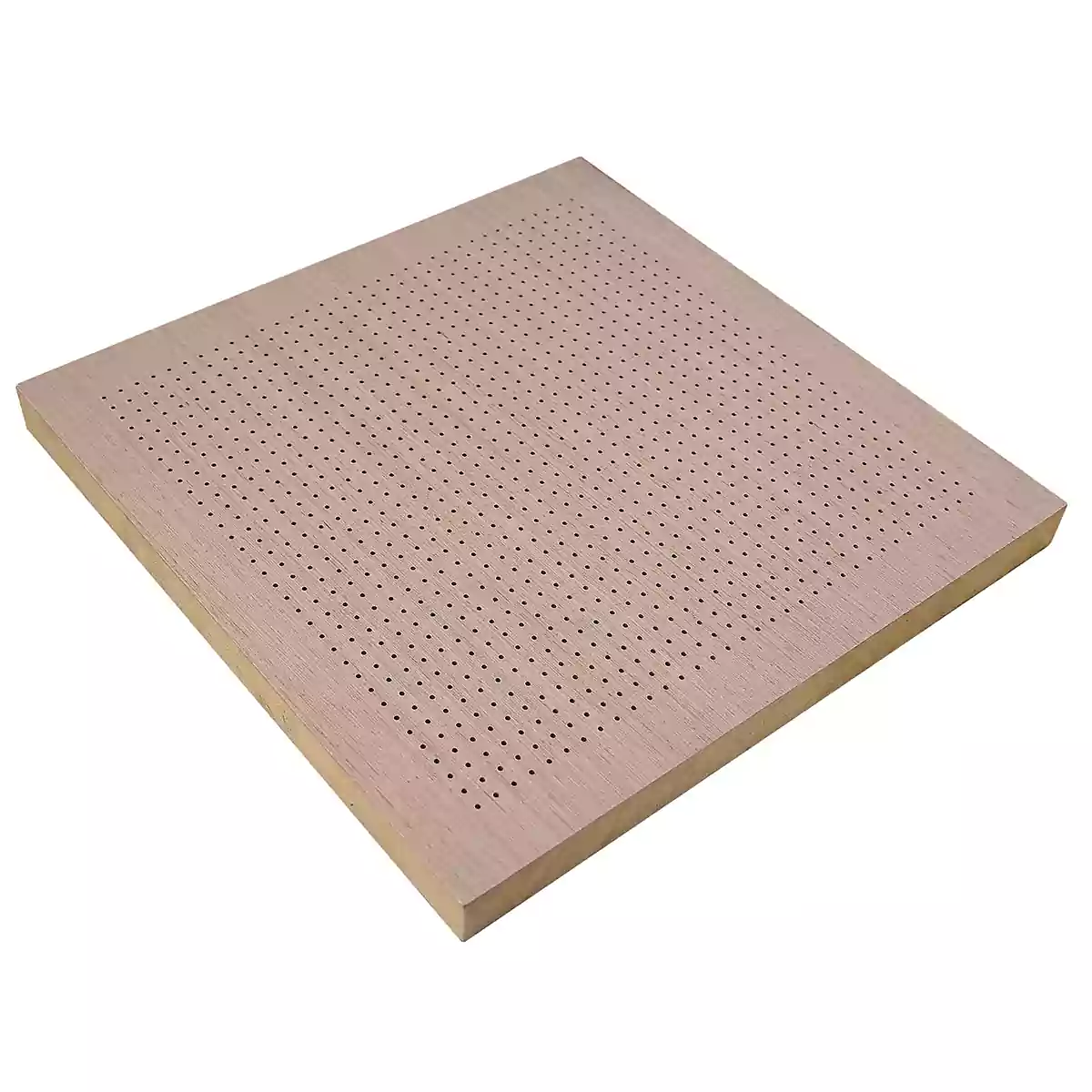

3. Board thickness: 12mm, 15mm, 18mm common thicknesses

4. Sound absorption coefficient:

1. Low frequency band ( 125Hz): 0.20-0.30

2. Mid-frequency band (500Hz): 0.50-0.60

3. High-frequency band (above 1000Hz): 0.70-0.90

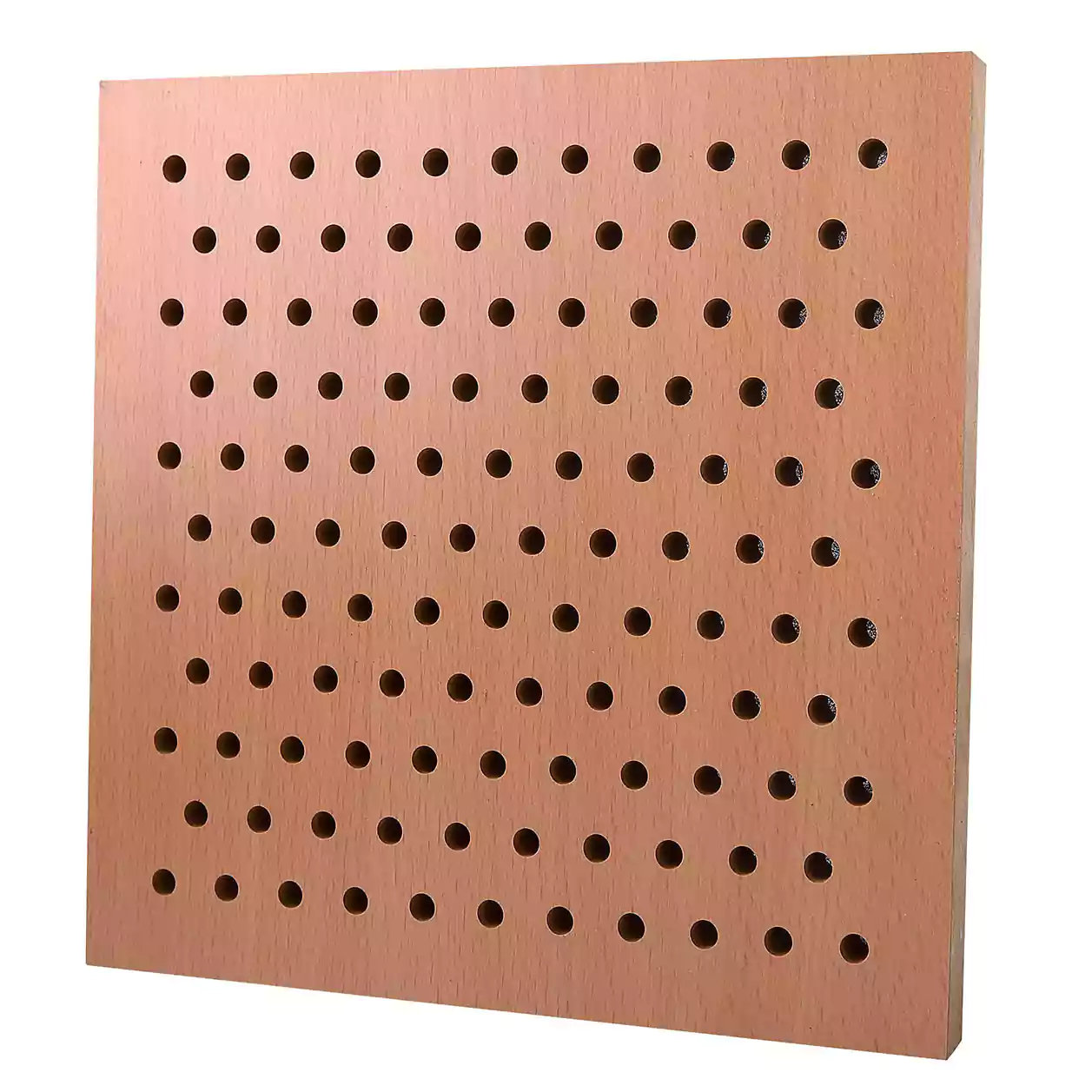

5. Perforation rate: generally 5%-20%, the higher the perforation rate, the better the sound absorption effect Remarkably

6. Aperture: generally Φ3mm, Φ6mm, Φ8mm

7. Groove spacing: 13/3mm, 14/2mm, etc.

8. Fire protection level: can reach B1, B2 level according to demand

9. Dimensions and specifications: The common size is 600mm× 600mm, 1200mm×2400mm, etc.

Products Description

1. Introduction to holewood sound-absorbing panels

Perforated wood sound-absorbing panels are a kind of material specially used for acoustic treatment. They are often used to absorb excess noise or echo in the room and improve the sound quality environment. The core material is usually density board (medium fiber board), and the sound absorption effect is achieved by drilling holes or grooves on its surface. Perforated wood sound-absorbing panels not only have good sound-absorbing properties, but are also environmentally friendly, beautiful, and durable. They are widely used in conference rooms, cinemas, recording studios, concert halls and other places that require high sound quality.

2. Working principle of perforated wood sound-absorbing panels

The sound absorption principle of perforated wood sound-absorbing panels is based on the principles of “impedance matching” and “sound wave attenuation”. By drilling holes or grooves in the density board, sound waves enter the holes or grooves and are reflected, attenuated, and ultimately absorbed within the material, reducing echoes and noise. The shape, size and spacing of the holes, as well as the thickness of the board, will directly affect the sound absorption effect.

3. Characteristics of perforated wood sound-absorbing panels

1. Efficient sound absorption: Through reasonable hole design, mid- and low-frequency echoes and noise can be effectively reduced and the acoustic environment improved.

2. Beautiful and diverse: The surface can be decorated in a variety of ways according to needs, such as veneer, spray paint or lamination to adapt to different styles of interior design.

3. Environmentally friendly and healthy: Made of environmentally friendly materials, with low formaldehyde emission, in line with national standards, and suitable for long-term indoor use.

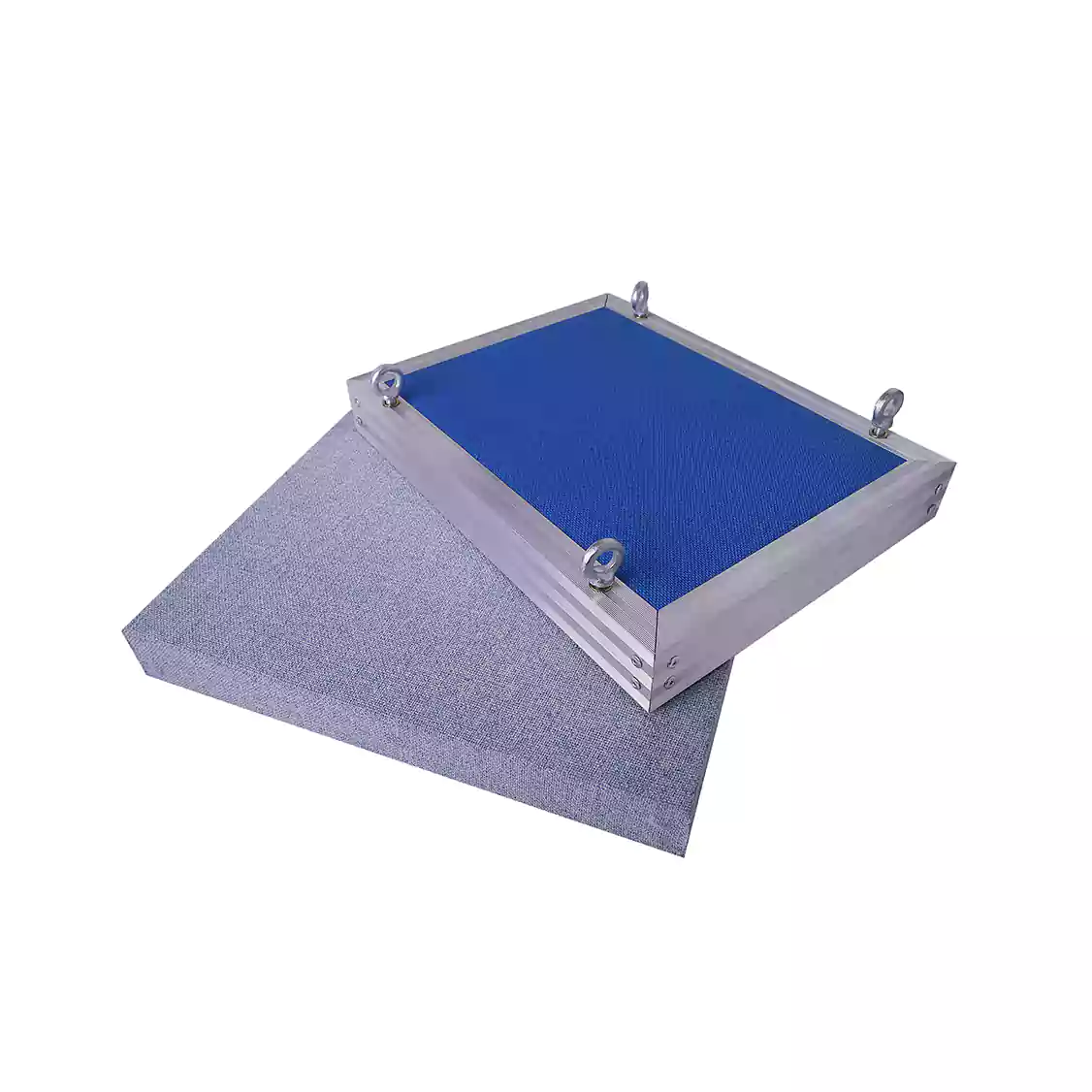

4. Easy to install: The plates have uniform specifications and are easy to install. They can be cut and combined according to actual needs.

4. Common parameters of perforated wood sound-absorbing panels

1. Base material: medium density fiberboard (MDF) or perforated gypsum board

2. Surface treatment: melamine veneer, veneer, spray paint, etc.

3. Board thickness: 12mm, 15mm, 18mm Common thickness

4. Sound absorption coefficient:

1. Low frequency band (125Hz): 0.20-0.30

2. Medium frequency band (500Hz): 0.50-0.60

3. High frequency band (above 1000Hz): 0.70-0.90

5. Perforation rate: generally 5%-20%, The higher the perforation rate, the more significant the sound absorption effect.

6. Aperture: generally Φ3mm, Φ6mm, Φ8mm

7. Slot spacing: 13/3mm, 14/2mm, etc.

8. Fire protection level: can reach B1 and B2 levels according to needs

9. Dimensions Specifications: Common sizes are 600mm×600mm, 1200mm×2400mm, etc.

5. Application areas of perforated wood sound-absorbing panels

1. Home theater: Used in home audio-visual entertainment rooms, it can effectively reduce echo and improve the movie-watching experience.

2. Recording studios and concert halls: Perforated wood sound-absorbing panels are often used in these high-demand places to help improve sound quality and reduce sound reflections.

3. Conference rooms and lecture halls: The use of sound-absorbing panels in these occasions can improve the clarity of speech and ensure that the speaker’s voice is not disturbed by echo.

4. Public places: such as hotel lobbies, restaurants, etc., use sound-absorbing panels to improve the quietness of the environment and enhance comfort.

6. Summary

Perforated wood sound-absorbing panels are a functional and decorative sound-absorbing material that can greatly improve the acoustic environment of the space and are suitable for a variety of places. Through the design and adjustment of parameters such as aperture, hole arrangement, and plate thickness, the sound absorption needs of different frequency bands can be met to ensure the best acoustic effect.

FAQ

Does the product support customization?

Yes, our products are all factory direct sales and can be customized according to customer needs.

What are the color options for Slatted Acoustic Panel surface?

Melamine Surface、Engineered Wood Surface、Natural Wood Surface、Baseboard Color

What is the thickness of the wood veneer of the Slatted Acoustic Panel?

Our product’s standard wood veneer thickness is 0.45mm and 0.25mm.

How many facets can a Slatted Acoustic Panel have?

Slatted Acoustic Panel has three covers and one cover.