Grooved wood sound-absorbing panels

Grooved wood sound-absorbing panels are acoustic panels designed to enhance sound quality by reducing noise and echo in various environments.

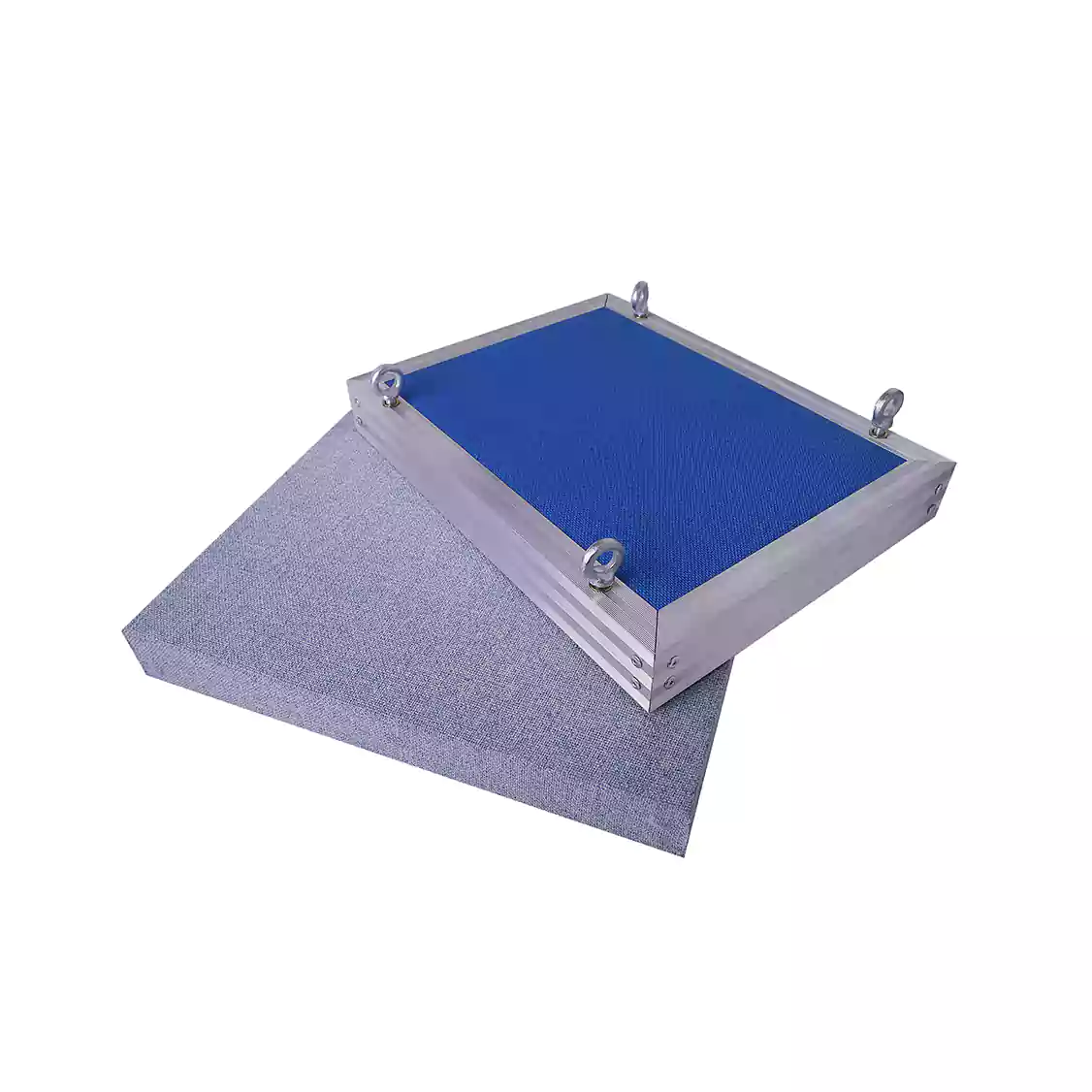

Products Description

Grooved wood sound-absorbing panels are acoustic panels designed to enhance sound quality by reducing noise and echo in various environments. These panels are typically made from high-quality wood, featuring a grooved surface that not only adds to their aesthetic appeal but also improves their sound-absorbing properties. The grooves increase the surface area, allowing the panels to effectively capture and dissipate sound waves.

These panels are commonly used in spaces such as recording studios, home theaters, offices, and conference rooms, where optimal acoustics are essential. They combine functionality with a natural, elegant look, making them a popular choice for both acoustic performance and interior design. Installation is usually straightforward, and the panels can be customized in terms of size, finish, and groove patterns to suit specific needs and preferences.

Material

-Usually natural wood or wood composite materials are used.

-Common types of wood include pine, oak, birch, etc.

Size

-Thickness: 10mm- 25mm.

-Width: 100mm – 200mm.

-Length: 1200mm – 2400mm.

Groove design

-The depth and width of grooves can affect the sound absorption effect, with common groove depths ranging from 2mm to 5mm and widths ranging from 5mm to 10mm.

-The arrangement of grooves can be linear, wavy, or other geometric patterns.

Sound absorption performance

-NRC (Noise Reduction Coefficient): typically between 0.4 and 0.8, depending on the groove design and backing material.

-Sound absorption frequency range: The effect is usually better in the mid to high frequency range (500Hz to 4000Hz).

Surface Treatment

-The surface can be treated with varnish, dye, or oil coating to enhance aesthetics and durability.

-Fireproof treatment can also be carried out to improve the fire rating.

Installation method

-It can be directly pasted on the wall or ceiling.

-The keel system can also be used for installation to facilitate adjustment and maintenance.

Environmental Performance

-Usually meets E1 or E0 environmental standards and has low formaldehyde emissions.

-Some products may have FSC (Forest Stewardship Council) certification to ensure the sustainability of wood sources.

Other features

-Moisture resistance: Some products have undergone special treatment and have a certain degree of moisture resistance.

-Wear resistance: Surface treatment can enhance wear resistance and extend service life.

These parameters may vary depending on the specific product model and manufacturer. It is recommended to consult the supplier in detail before purchasing to obtain accurate product specifications and technical parameters.

FAQ

Does the product support customization?

Yes, our products are all factory direct sales and can be customized according to customer needs.

What are the color options for Slatted Acoustic Panel surface?

Melamine Surface、Engineered Wood Surface、Natural Wood Surface、Baseboard Color

What is the thickness of the wood veneer of the Slatted Acoustic Panel?

Our product’s standard wood veneer thickness is 0.45mm and 0.25mm.

How many facets can a Slatted Acoustic Panel have?

Slatted Acoustic Panel has three covers and one cover.