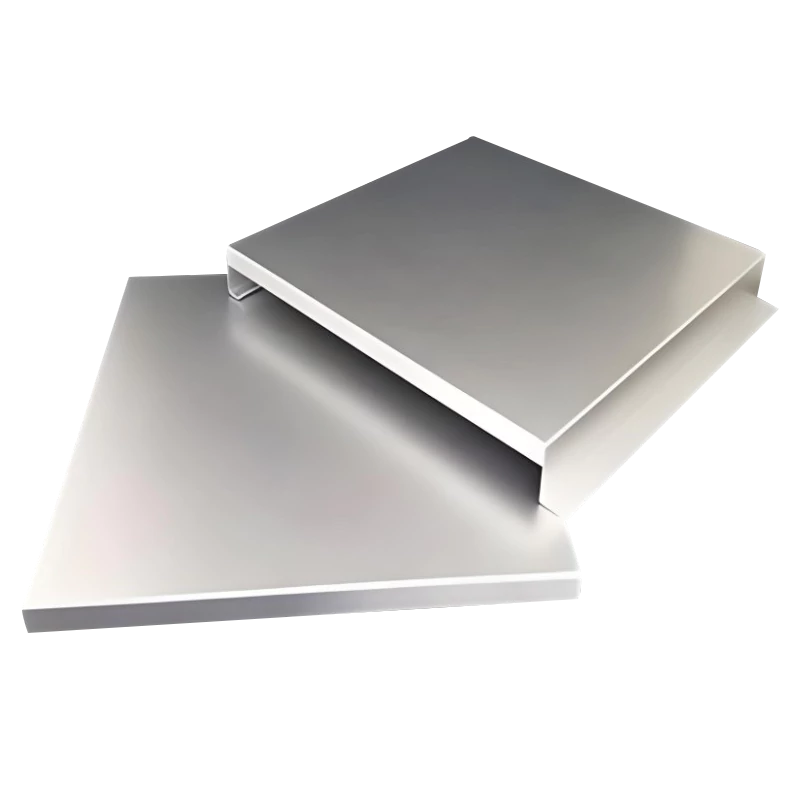

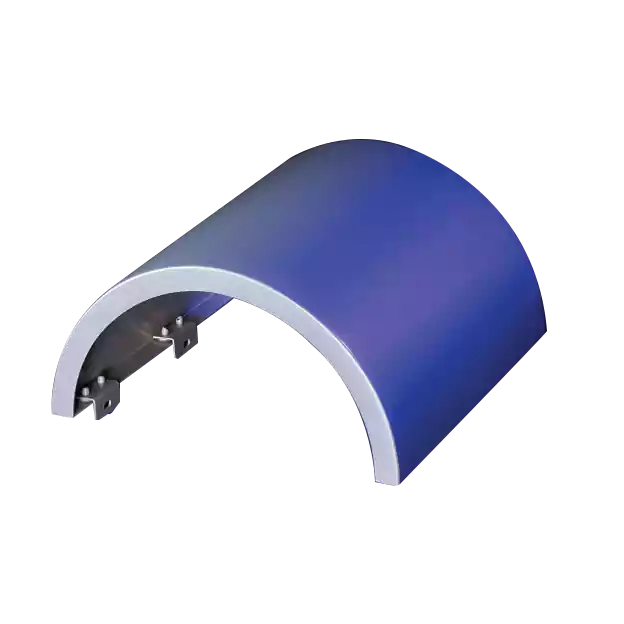

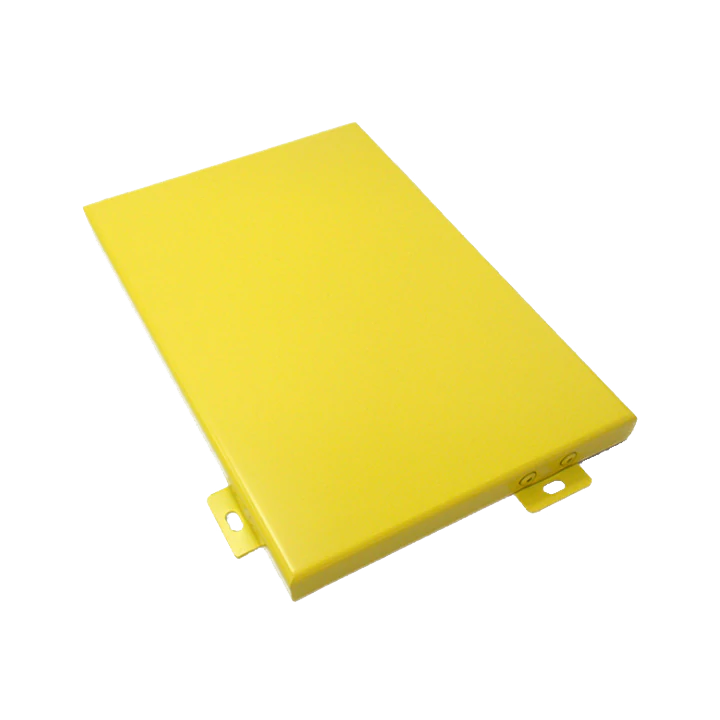

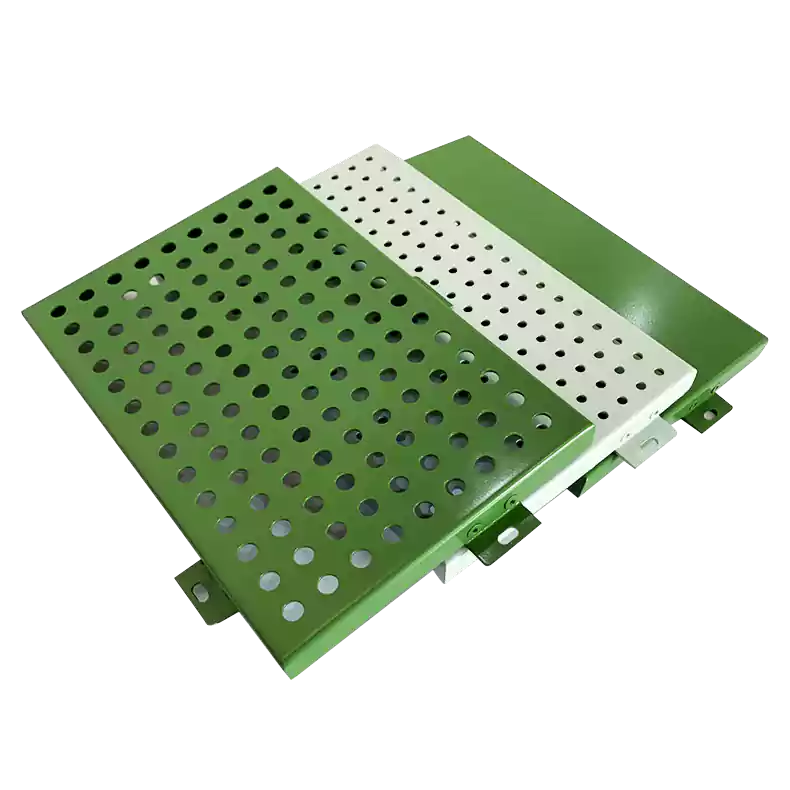

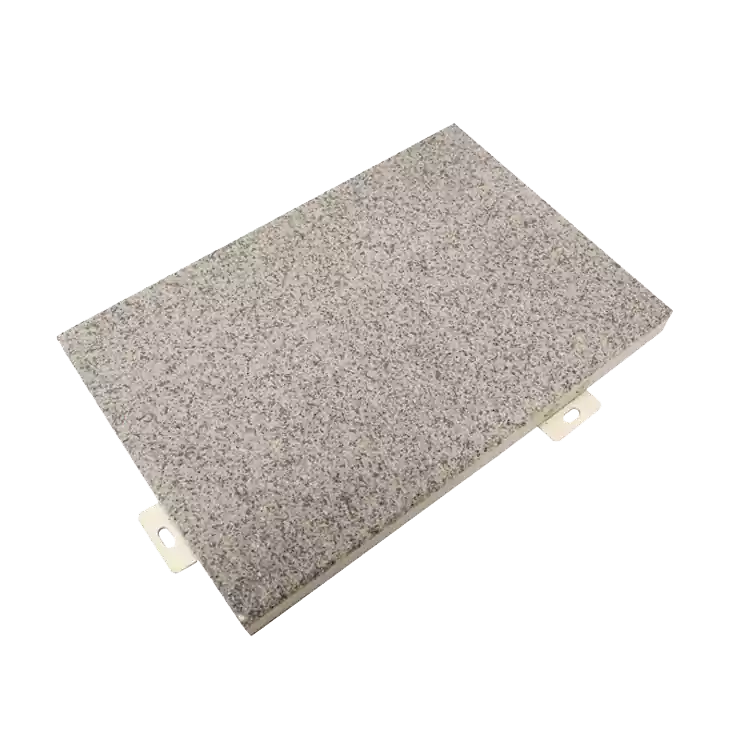

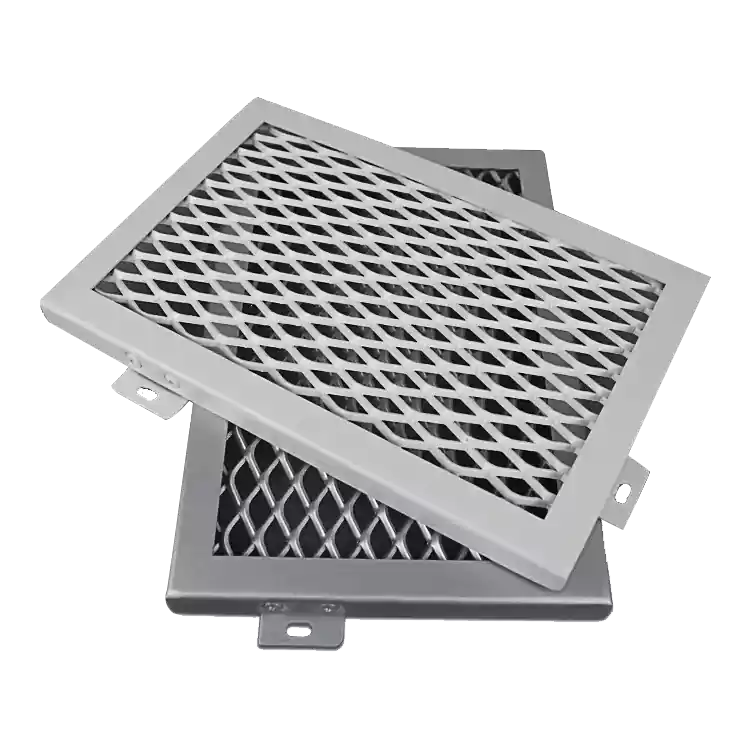

Anodized aluminum veneer

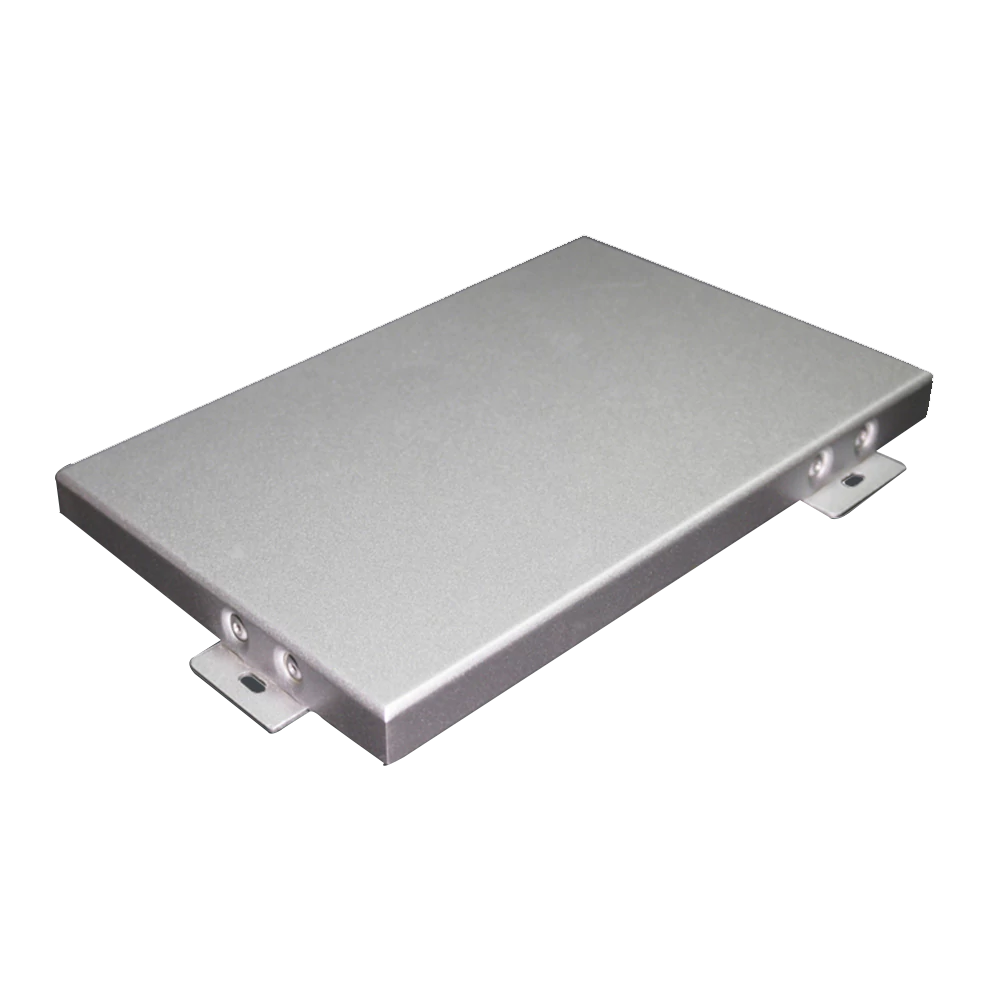

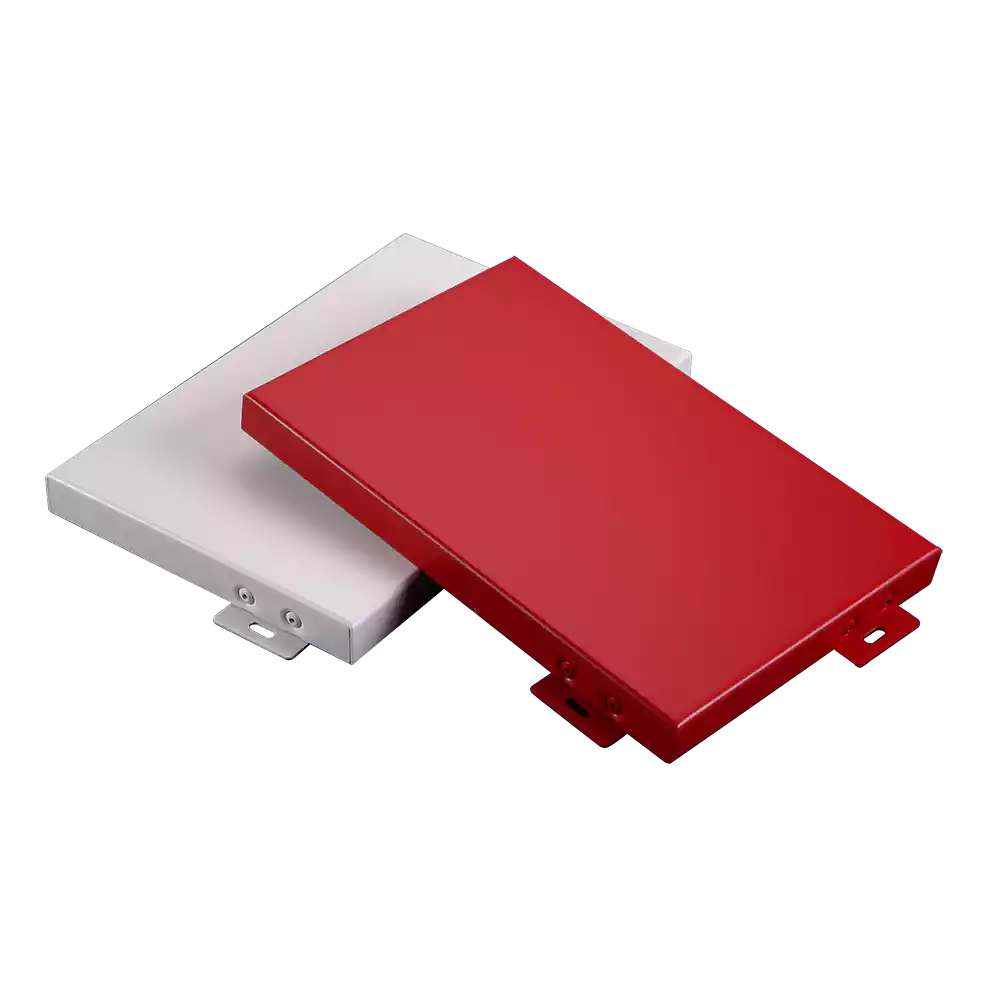

Material: Aluminum alloy (AA3003/AA5005)

Thickness: 1.0mm/1.5mm/2.0mm (can be customized)

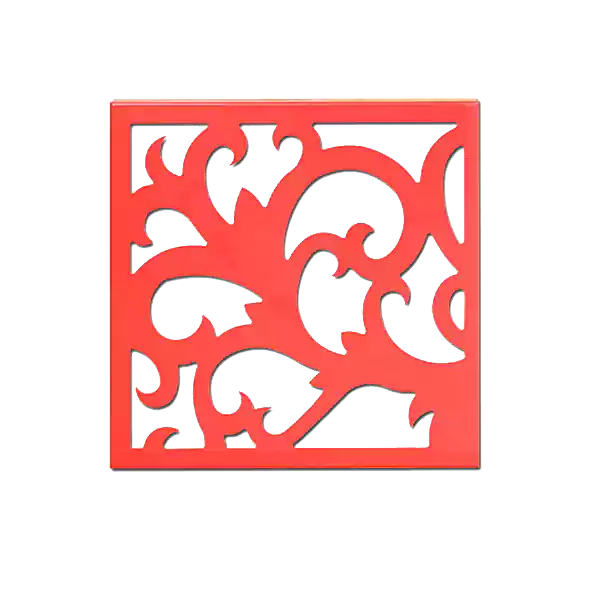

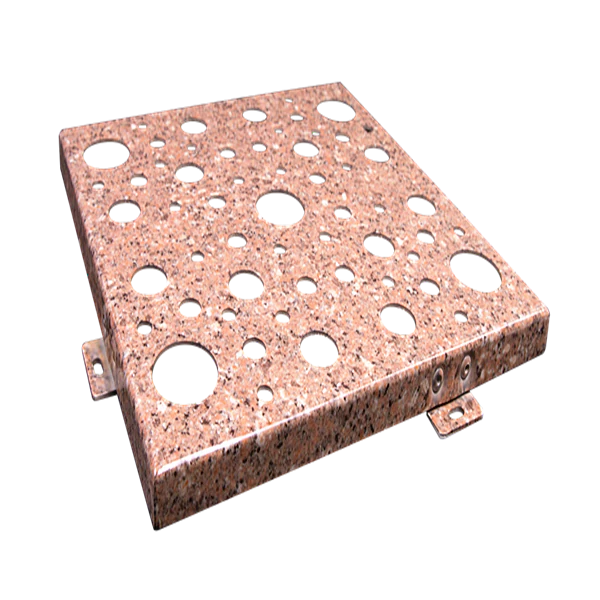

Surface treatment: anodizing, fluorocarbon spraying, wood grain transfer, etc.

Size: Regular size 1220mm x 2440mm (can be customized)

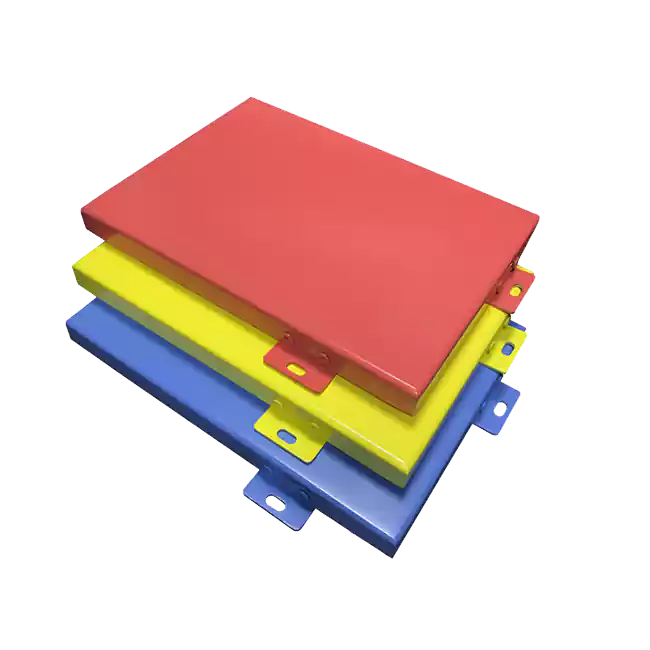

Color: There are dozens of optional colors, and customization is supported

Weight: about 3.5-4.5 kg/m² (depending on thickness)

Temperature resistance: -40°C to +80°C

Wind pressure resistance: ≥ 3000Pa

Fire protection grade: B1 level (in line with national standards)