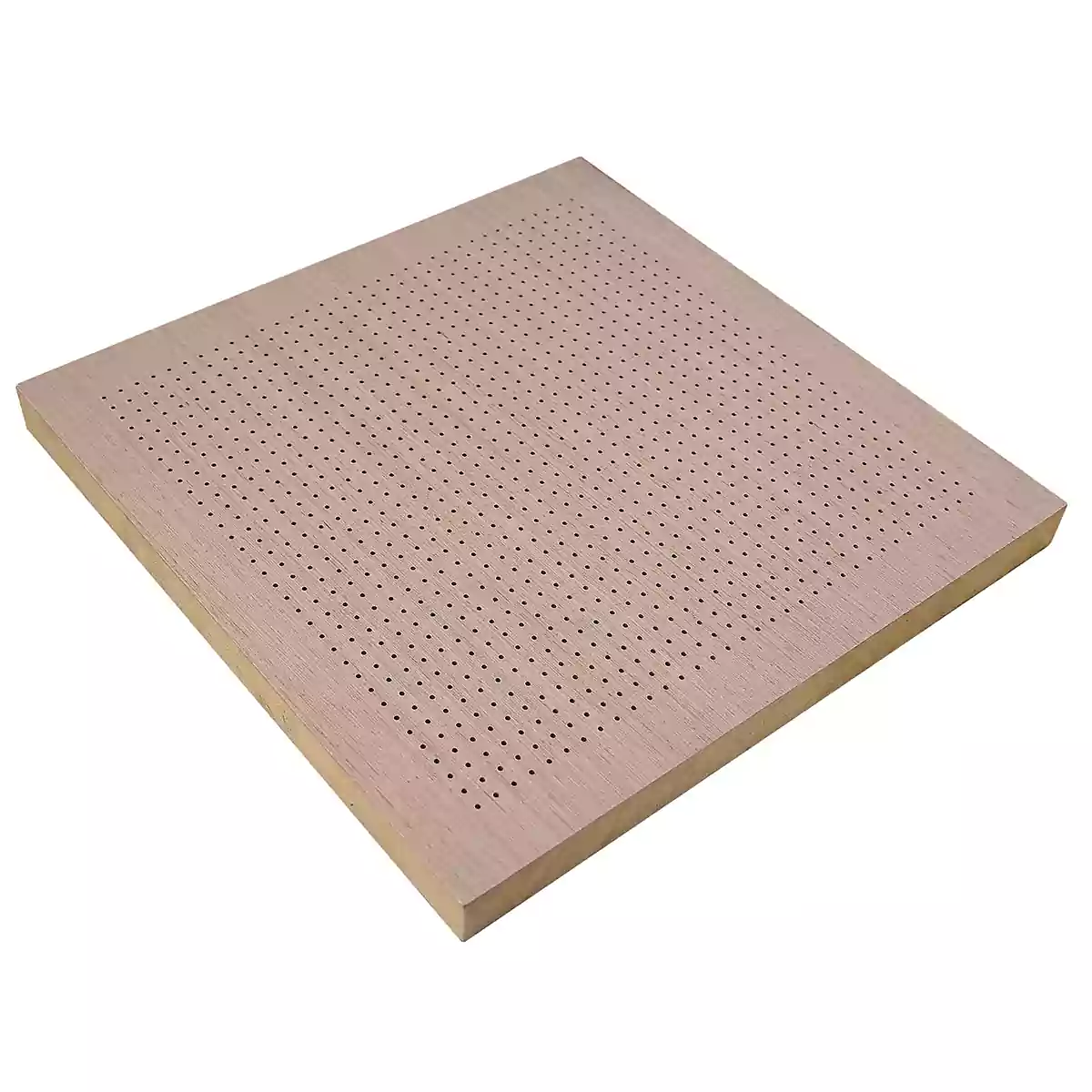

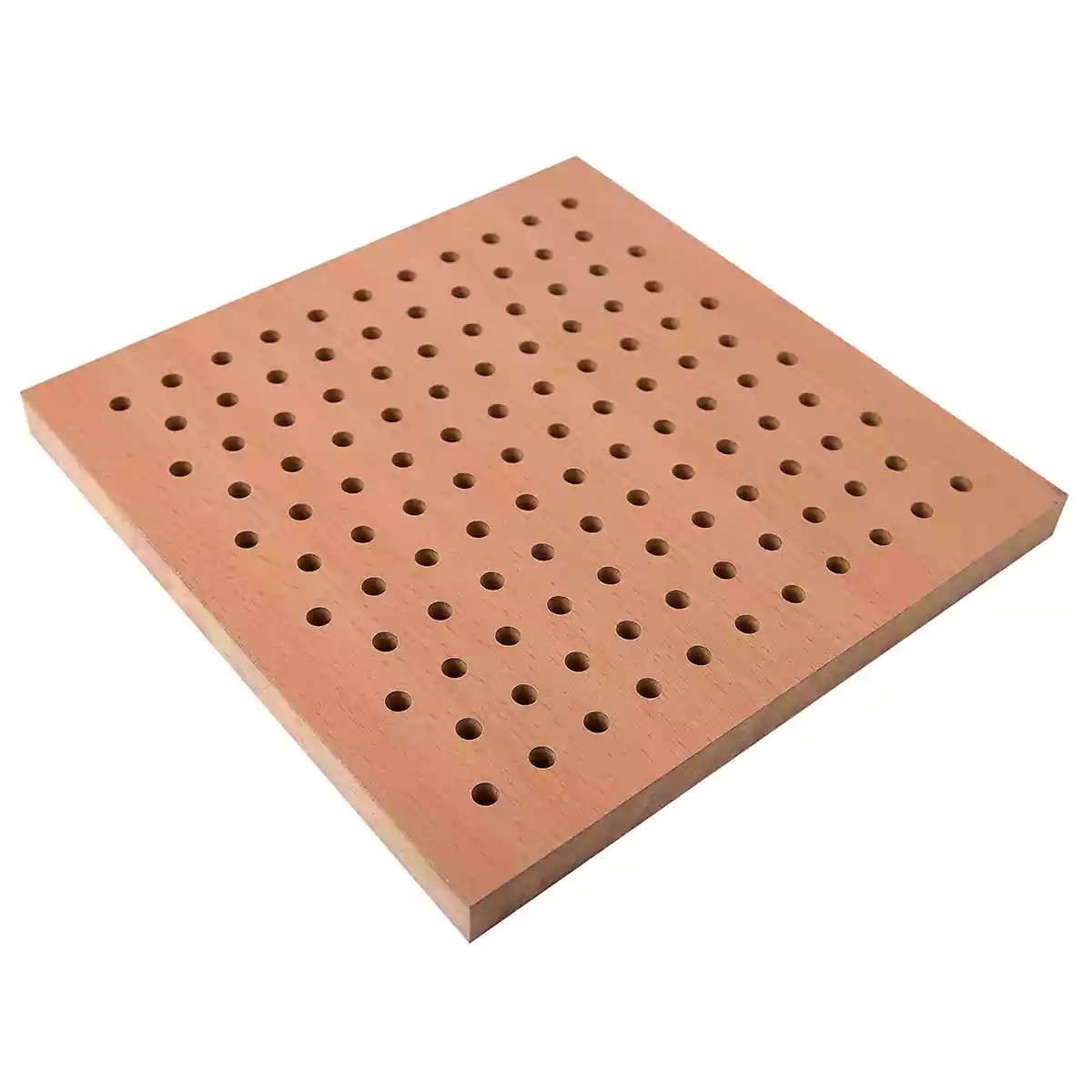

Grooved wood sound-absorbing panels

1. Material: Usually medium density fiberboard (MDF) or other high-density wood materials are used.

2. Specifications:

1. Common sizes: 2440mm × 128mm, 2440mm × 197mm, etc. Other specifications can be customized according to needs.

2. Thickness: 12mm, 15mm, 18mm and other common thicknesses. The greater the thickness, the better the sound absorption effect.

3. Surface treatment:

1. Wood grain veneer: A common surface treatment method, the texture of imitation wood is beautiful and natural.

2. Spray painting: A variety of colors are available to meet different design needs.