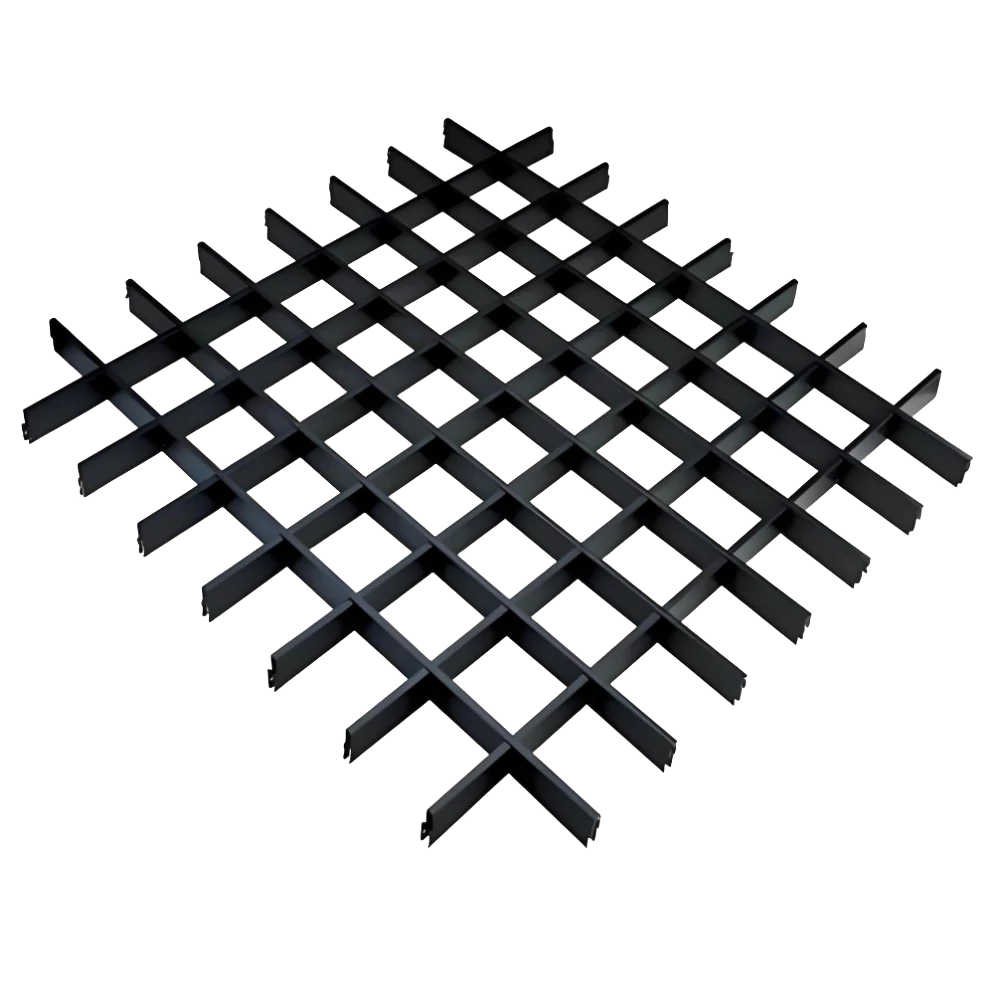

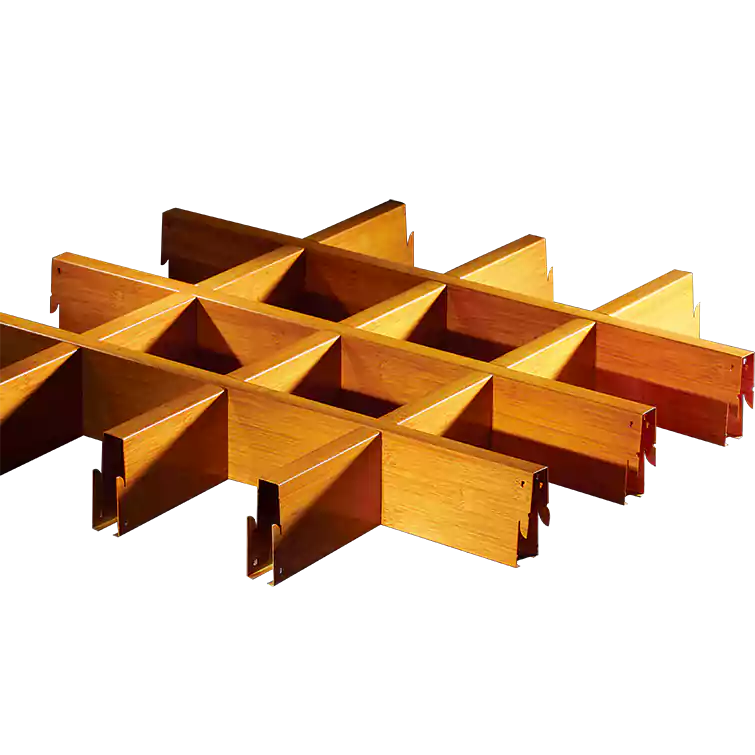

Aluminum alloy grille ceiling system

Products Description

Aluminum grating is a material widely used in construction and decoration fields. Its light weight, high strength and excellent corrosion resistance make it an ideal choice. Aluminum grilles are mainly used in ceilings, wall decorations and ventilation systems, which can effectively improve the aesthetics and practicality of the space.

1. Application of aluminum grille

Aluminum gratings are widely used in construction, interior decoration, public facilities and industrial fields. Main applications include:

Building facade: As an exterior facade material, aluminum grilles can not only provide good ventilation effects, but also enhance the aesthetics of the building. They are often used in commercial buildings, exhibition halls, etc.

Indoor ceilings: In indoor spaces, aluminum grilles can be used as ceiling materials to create a transparent, modern space and facilitate the installation of lighting equipment and air conditioning systems.

Partitions and screens: Aluminum grilles can be used as indoor partitions, providing flexibility for space division while ensuring the penetration of light.

Gardening and Landscape Design: In gardening, aluminum grilles can be used for decoration on balconies, flower beds, courtyards, etc. to add natural beauty.

Industrial applications: In some industrial environments, aluminum gratings are used as anti-skid walkways, work platforms, etc., with high load-bearing capacity and corrosion resistance.

2. Parameters of aluminum grille

When choosing aluminum grating, there are several key parameters to consider:

Material: usually made of aluminum alloy, which has the characteristics of light weight, high strength and corrosion resistance.

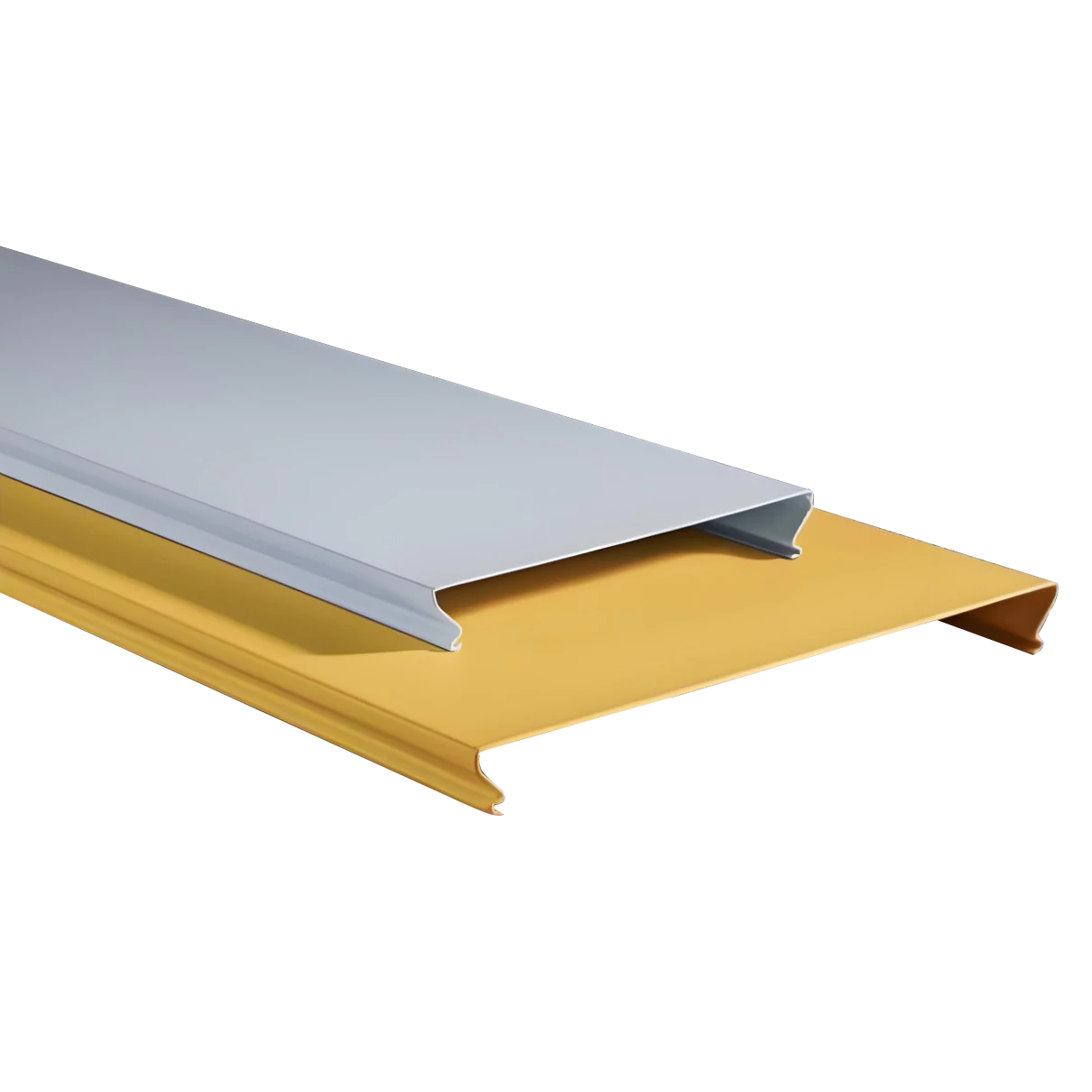

Size: The size of the aluminum grille can be customized according to needs. Common thicknesses are 1.0mm, 1.5mm, 2.0mm, etc. There are also many options for width and length.

Hole pattern: Aluminum gratings have various hole patterns, including square holes, round holes, strip holes, etc. Choose the appropriate hole pattern according to different application scenarios.

Surface treatment: The surface of the aluminum grille can be anodized, spray-coated, etc. to enhance wear resistance and aesthetics.

Load-bearing capacity: The load-bearing capacity depends on the structural design of the aluminum grating, which can usually be tested and verified based on design requirements.

3. Installation method of aluminum grille

The installation process of aluminum grille is relatively simple. The following are the general installation steps:

Preparation:

1. Make sure the installation area is clean and flat, and check whether the base is stable.

2. Prepare the required aluminum grilles and installation accessories (such as hangers, screws, etc.) according to the design drawings.

Measure and mark:

1. Use a tape measure to measure the installation location to ensure that the installation height and levelness of the aluminum grille meet the design requirements.

2. Mark the installation point on the wall or ceiling.

Mounting bracket:

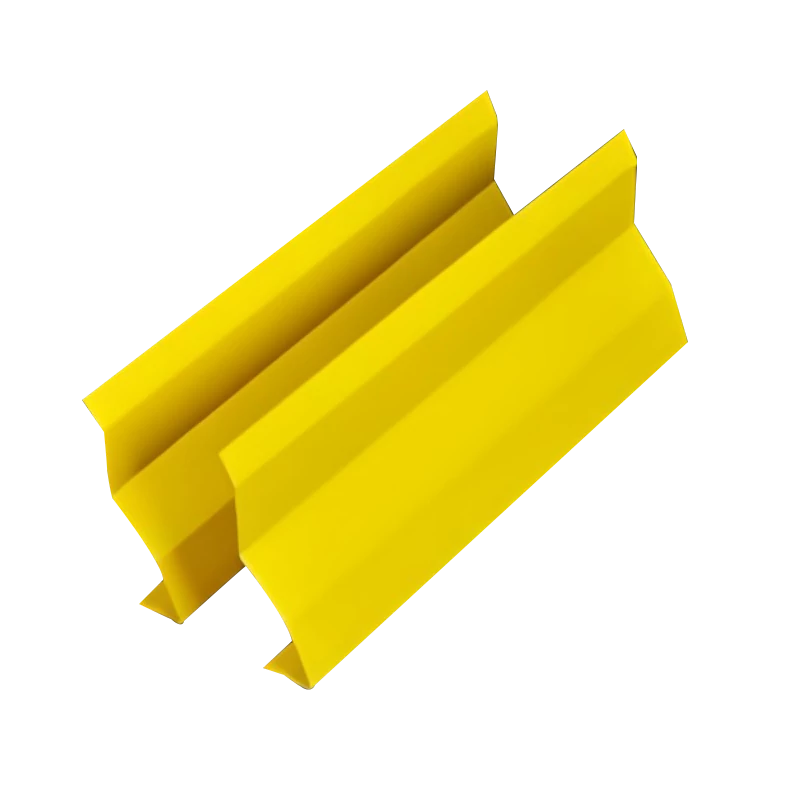

1. Install the bracket according to the marked position. The bracket should be firmly fixed to ensure that it can bear the weight of the aluminum grille.

Install aluminum grille:

1. Connect the aluminum grille to the bracket according to the design requirements and fix it with screws to ensure that each joint is stable.

2. For ceiling installation, it is necessary to ensure that the gap between the aluminum grille and the suspended ceiling meets the design requirements.

Final check:

1

1. Check whether all connection points are firm and ensure the flatness and level of the aluminum grille.

2. Clean the installation site and remove excess tools and materials.

in conclusion

Aluminum grating has become an important material in modern architecture and decoration with its unique aesthetics, excellent performance and wide range of application scenarios. Through reasonable selection of parameters and scientific installation methods, the advantages of aluminum grilles can be fully utilized to add fashion and functionality to the space.

FAQ

Does the product support customization?

Yes, our products are all factory direct sales and can be customized according to customer needs.

What are the color options for Slatted Acoustic Panel surface?

Melamine Surface、Engineered Wood Surface、Natural Wood Surface、Baseboard Color

What is the thickness of the wood veneer of the Slatted Acoustic Panel?

Our product’s standard wood veneer thickness is 0.45mm and 0.25mm.

How many facets can a Slatted Acoustic Panel have?

Slatted Acoustic Panel has three covers and one cover.