Indoor dense aluminum veneer

Material: high strength aluminum alloy

Thickness: usually 2mm, 3mm, 4mm optional

Size: Standard size is 1220mm x 2440mm, other sizes can be customized

Surface treatment: electrostatic spraying, anodizing, wood grain transfer, etc.

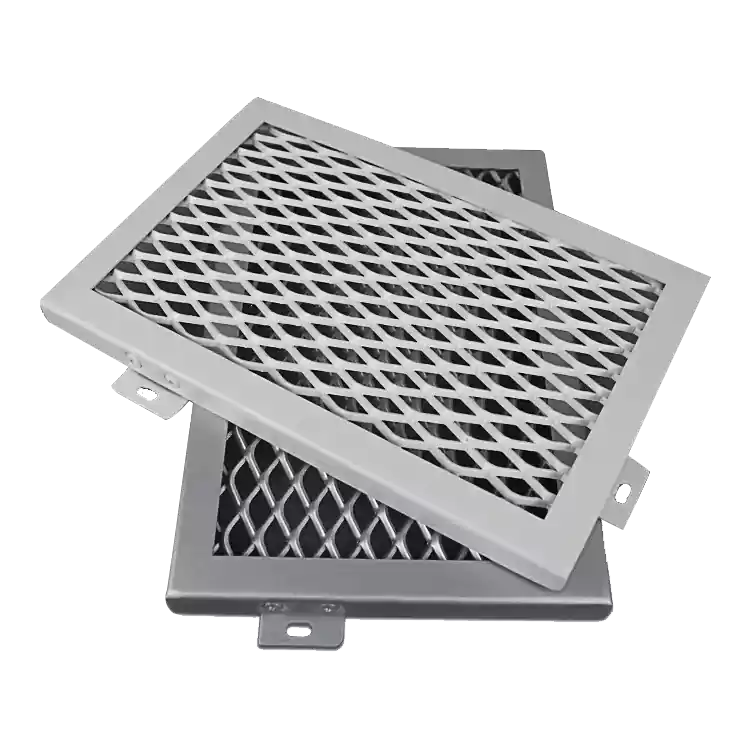

Dense splicing method: Seamless splicing design, the minimum splicing gap can be up to 1mm

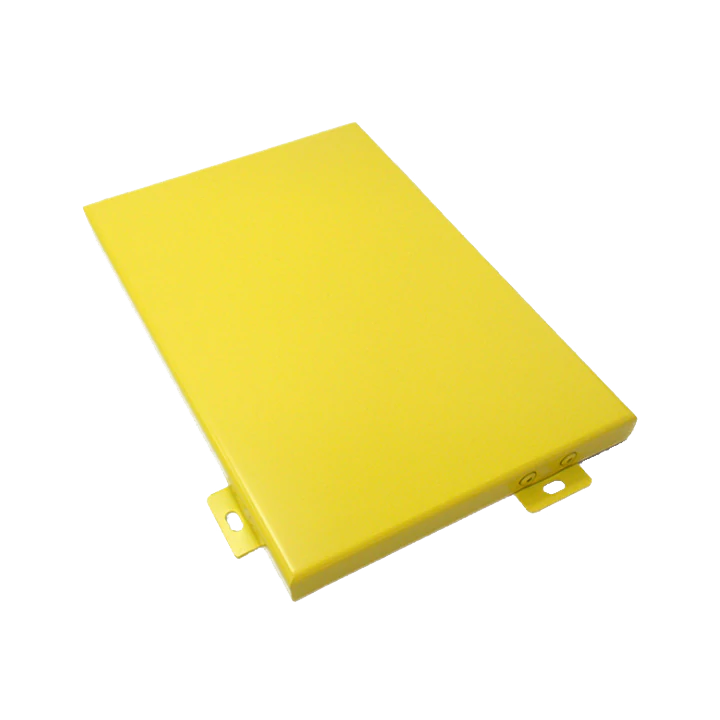

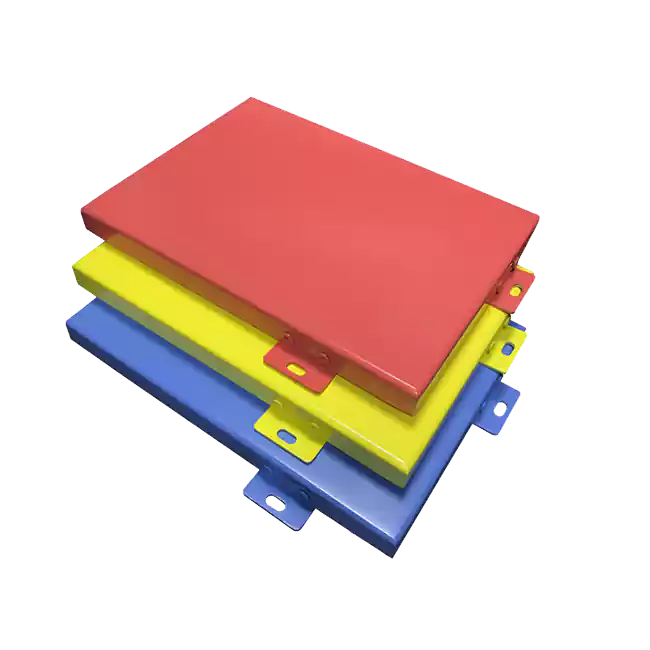

Color selection: A variety of colors are available to meet different design needs

Fire protection level: reaches A2 level fire protection standard

Wind pressure resistance: After rigorous testing, it has good wind pressure resistance

Products Description

Indoor dense aluminum veneer is a high-performance building decoration material that is widely used in commercial spaces, office buildings, hotels and other indoor environments. It is made of high-quality aluminum alloy as the base material and treated with special processes to have excellent aesthetics and practicality.

Product parameters

Material: high strength aluminum alloy

Thickness: usually 2mm, 3mm, 4mm optional

Size: Standard size is 1220mm x 2440mm, other sizes can be customized

Surface treatment: electrostatic spraying, anodizing, wood grain transfer, etc.

Dense splicing method: Seamless splicing design, the minimum splicing gap can be up to 1mm

Color selection: A variety of colors are available to meet different design needs

Fire protection level: reaches A2 level fire protection standard

Wind pressure resistance: After rigorous testing, it has good wind pressure resistance

Features

Beautiful and elegant: Various surface treatments and color choices make the indoor space more modern and artistic.

Lightweight and high strength: Aluminum veneer is lightweight and easy to transport and install, but has excellent strength and durability.

Excellent fire protection performance: complies with national fire protection standards to ensure the safety of the use environment.

Excellent processing performance: secondary processing such as cutting and drilling can be performed according to design requirements, and can be flexibly adapted to various design needs.

Easy to clean and maintain: The surface is smooth, dirt is not easy to adhere, and cleaning and maintenance are simple.

Environmentally friendly materials: Aluminum is recyclable and conforms to modern environmental protection concepts.

Installation instructions

Preparation: Before installation, make sure the wall is flat, dry and clean of surface debris.

Support structure: According to the size and weight of the aluminum veneer, a reasonable support structure is designed, generally using aluminum profiles or steel keels for support.

Fixing method: Use rivets, screws and other fasteners to fix the aluminum veneer to the support structure to ensure firmness and reliability.

Splicing processing: Carry out splicing according to the design drawings to ensure that the splicing gaps are consistent, and use special sealant to treat the gaps to improve the aesthetics and waterproof performance.

Acceptance: After the installation is completed, conduct an overall acceptance to ensure that there is no color difference, no deformation, and it is firm and stable.

Conclusion

Indoor dense aluminum veneer has become an indispensable material choice in modern interior design due to its excellent performance and beautiful appearance. Whether it is a high-end office building or a refined hotel, aluminum veneers can create unique visual effects and a comfortable space experience.

FAQ

Does the product support customization?

Yes, our products are all factory direct sales and can be customized according to customer needs.

What are the color options for Slatted Acoustic Panel surface?

Melamine Surface、Engineered Wood Surface、Natural Wood Surface、Baseboard Color

What is the thickness of the wood veneer of the Slatted Acoustic Panel?

Our product’s standard wood veneer thickness is 0.45mm and 0.25mm.

How many facets can a Slatted Acoustic Panel have?

Slatted Acoustic Panel has three covers and one cover.